Technical Information / Technical Information / Technical Spring Data

Technical Spring Data

Technical Spring Data

DYNALLOY, Inc... Home to the Flexinol® Actuator Wires

Flexinol® Actuator Spring Technical and Design Data

Flexinol® actuator springs can be an alternative to straight Flexinol® actuator wires for applications with low force and high travel requirements. These springs cancontract and relax multiples of their length. When Flexinol® actuator springs are used within the correct parameters high cycle life is expected. Pricing can be found clicking here, and adding crimps on the ends is also possible.

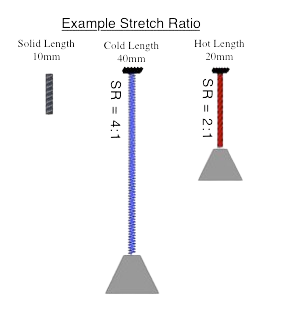

SR = L/SL

Stretch Ratio is defined as any length "L" over the solid length "SL", in any state, hot or cold. For example a spring with a SR of 4 cold and 2 hot, assuming a solid lengthof 10mm would then be 20mm hot, and 40mm cold.

SR = L/SL

Stretch Ratio is defined as any length "L" over the solid length "SL", in any state, hot or cold. For example a spring with a SR of 4 cold and 2 hot, assuming a solid lengthof 10mm would then be 20mm hot, and 40mm cold.

SR = L/SL

Technical Information

While these values will vary depending on how the springs are used, are still a reasonable starting point for a design. In your calculations please reference the displacement per coil in conjunction with the stretch ratio to help identify the appropriate length spring to purchase.

Flexinol® Actuator Spring Data Table

The following chart gives rough guidelines as to how much current and force to expect with various Flexinol® actuator spring.

|

Spring Wire Diameter in(mm) Outer Diameter in(mm) |

SR Cold,

SR Hot *

The Stretch Ratio "SR" and Displacement values are typically accurate, but remain approximate values.

|

Displacement / Coil in(mm) *

The Stretch Ratio "SR" and Displacement values are typically accurate, but remain approximate values. |

Resistance on Straight Wire ohms/inch (ohms/mm) |

Heating Pull Force **

The Heating pull force is based on ~ 25,000 psi (172 MPa), which for many applications is the maximum safe stress for the wire. However, many applications use higher and lower stress levels. This depends on the specific conditions of a given design. The cooling deformation force is based on ~10,000 psi (70 MPa), which is a good starting point in a design. However, this value can also vary depending on how the material is used pounds (grams) |

Cooling Deformation Force **

The Heating pull force is based on 25,000 psi (172 MPa), which for many applications is the maximum safe stress for the wire. However, many applications use higher and lower stress levels. This depends on the specific conditions of a given design. The cooling deformation force is based on 10,000 psi (70 MPa), which is a good starting point in a design. However, this value can also vary depending on how the material is used. pounds (grams) |

Approximate ***

The contraction time is directly related to current input. The figures used here are only approximate since room temperatures, air currents, and heat sinking of specific devices vary. On small diameter wires (diameters less than or equal to 0.006" (0.15mm) diameter) currents which heat the wire in 1 second can typically be left on without over-heating it. Both heating and cooling times can be dramatically changed, see section 3 of the " technical characteristics" for more information. Current for 2 Second Contraction(A) |

Cooling Time 194°F, 90°C "HT" Wire ****

Approximate cooling time, at room temperature in static air, using a vertical wire. The last 0.5% of deformation is not used in these approximations. For more information on the difference between the 90°C "HT" wire and 70°C "LT" wire please see a temperature strain plot on the bottom of this "Tech Sheet. LT = Low Temperature and HT = High Temperature Flexinol® Actuator wire. (seconds) |

|---|---|---|---|---|---|---|---|

| 0.020 (0.51), 0.136 (3.45) | 6.5, 3.5 | 0.06 (1.5) | 0.11 (4.33) | 0.536 (243.3) | 0.215 (97.32) | 3.4 | 15.0 |

| 0.015 (0.381), 0.10 (2.54) | 6.5, 3.5 | 0.04 (1.1) | 0.21 (8.27) | 0.307 (139.3) | 0.122 (55.72) | 1.9 | 9.0 |

| 0.008 (0.203), 0.054 (1.37) | 6.5, 3.5 | 0.02 (0.6) | 0.74 (29.13) | 0.089 (39.3) | 0.035 (15.94) | 0.7 | 3.0 |

*The Stretch Ratio "SR" and Displacement values are typically accurate, but remain approximate values.

** The Heating pull force is based on ~ 25,000 psi (172 MPa), which for many applications is the maximum safe stress for the wire. However, many applications use higherand lower stress levels. This depends on the specific conditions of a given design. The cooling deformation force is based on ~10,000 psi (70 MPa), which is a goodstarting point in a design. However, this value can also vary depending on how the material is used.

*** The contraction time is directly related to current input. The figures used here are only approximate since room temperatures, air currents, and heat sinking of specificdevices vary. Both heating and cooling can be dramatically changed (see section 3 of the technical characteristics).

**** Approximate cooling time, at room temperature in static air, using a vertical spring. The last 0.5% of deformation is not used in these approximations. HT = HighTemperature Flexinol® Actuator Spring.